At AdvanTech Plastics, we are a premier provider of plastic injection molding solutions. One of our core areas of specialization is insert molding, a one-step process that involves over molding thermoplastic resin around preformed components. This service allows us to produce parts and products for a wide range of industries.

What Is Insert Molding, and How Does It Work?

Insert molding is an injection molding method that involves placing a prefabricated component—generally made from metal—and then injecting molten plastic material into a mold. The result is a complete product assembly consisting of molded plastic partially or completely surrounding the insert.

This process is highly similar to over molding, which combines multiple plastic materials to form a single product. The main difference between the two is that insert molding uses a preformed insert, while over molding requires the interior component to be molded before the outer layers can be added.

Benefits

Compared to other manufacturing methods, there are several benefits to the manufacturer and end-users, such as:

- Improved component reliability

- Increased component strength and stability

- Reduced assembly and labor costs

- Decreased product size and weight

- Enhanced design flexibility

AdvanTech’s Insert Molding Capabilities

The injection molding team at AdvanTech Plastics maintains a broad selection of insert molding capabilities. Armed with extensive experience and advanced manufacturing equipment, we can create high-quality molded plastic components for a variety of industries and applications.

The one-step process allows us to manufacture products in less time and at a lower cost with little or no secondary processing or finishing needed. We can accommodate a broad selection of materials for the over molding stage, such as polypropylene (PP), thermoplastic elastomer (TPE), and glass-filled nylon, and for the inserts. Production capacities range from prototype to full production quantities.

Types of Inserts

The inserts used in operations can be made from different materials depending on the exact product and production specifications. Some of the most used materials are:

- Aluminum

- Brass

- Copper

- Plastics

- Rare earth metals

- Stainless steel

Applications

The insert molding process is used to create molded components for many industries. At AdvanTech Plastics, we often provide insert molded parts and products to the following:

- Electronics. We use the insert molding process to make a variety of electronic components, including relays, switches, and wire harnesses.

- General industrial. We use the process to manufacture handles, latches, and other general components used across many different industries.

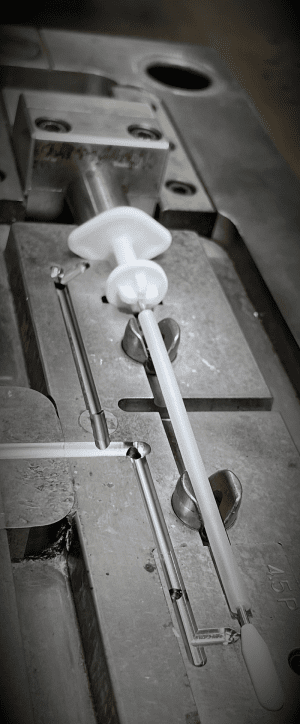

- Medical. We use the insert molding process to produce critical medical devices, such as obturators.

Superior Insert Molding Solutions from AdvanTech Plastics

Insert molding is an ideal manufacturing solution for many molded components. By combining the molding and assembly stages into a single process, it enables parts and products to be created in less time and at a lower cost. Additionally, the results often offer similar or better characteristics than components made through other methods.

Whether you need an insert molded component for the electronics, general industrial, medical, or another industry, the experts at AdvanTech Plastics are here to help. Our end-to-end molded plastic product solutions ensure you receive assistance from initial design to full-scale production, so you can trust us to deliver the parts you need when you need them.

For more information on our services, contact us today. To partner with us on your next project, request a quote.