Two-shot injection molding offers many advantages over single-shot injection molding, allowing manufacturers to produce multiple complex products using a single process. AdvanTech Plastics is proud to offer full-service custom plastic injection molding services, including Two-shot injection molding. Our Two-shot injection molding capabilities are designed to provide cost-effective solutions that meet customer specifications with reduced lead times and minimal waste.

What Is Two-Shot Injection Molding?

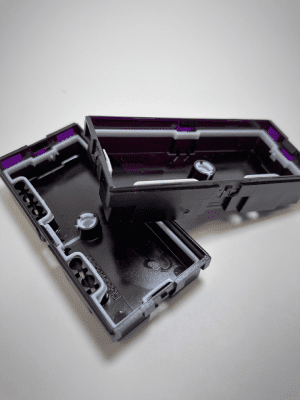

Two-shot injection molding involves the process of injecting two materials and/or colors into a mold to produce one or more components.

The two-shot injection molding process is as follows:

- Liquified plastic is injected into a mold and cooled to create a solid part.

- Once cooled, the part is transferred to a second mold where it receives a second shot of liquified plastic.

- The two resins form a molecular bond, and then the molded part is cooled and ejected.

- The process continues until the desired amount of parts is made.

Two-Shot Injection Molding Capabilities

At AdvanTech Plastics, we provide support from start to finish, including design consultation, product development, engineering, pad printing, sonic welding, and finishing services. Our dual-shot molding capabilities include a range of sizes, materials, and tolerances to suit a variety of applications. We can manufacture products with a shot range from 1.6 to 46 oz with clamping forces of 55 to 400 tons, and we can meet precise tolerances of +/-0.002 inches.

At AdvanTech, we work with the following materials:

- Thermoplastics

- Polyvinyl chloride

- PEEK

- Polystyrene

- PET

- Polypropylene

- Nylon

- Polycarbonate

- HDPE/LDPE

- Copolymer polypropylene

- ABS

- Acrylic

- Acetal

We are proud to offer our services to a wide range of industries, including telecommunications, printing, pharmaceutical, food & beverage, medical, dental, electronic, and automotive.

Advantages of Two-Shot Injection Molding

Two-shot injection molding boasts a range of advantages over typical single-shot molding. The primary benefits are:

- Part Consolidation. Two-shot injection molding reduces assembly requirements by combining parts in a single process, which significantly cuts costs.

- Efficiency. This process eliminates the need for welding or joining after the molding process, allowing for reduced lead times and labor requirements.

- Quality. Two-shot injection molding minimizes waste and increases tolerance capabilities while repeating designs flawlessly.

- Ability to Handle Complexity. This process is capable of handling complex geometries and textures, along with various colors and materials.

Two-Shot Injection Molding From AdvanTech Plastics

Two-shot injection molding is a highly beneficial and efficient process capable of producing many complex parts. AdvanTech Plastics offers a range of two-shot injection molding capabilities, including various materials, sizes, and tolerances, to suit the needs of your requirements and specifications.

As an ISO 9001:2015 & ISO 13485:2016 certified and AIB approved company, the engineers at AdvanTech Plastics can deliver cost-effective, high-quality products with quick turnaround times. For more information, or to get started on your custom two-shot injection molding solution, request a quote today.