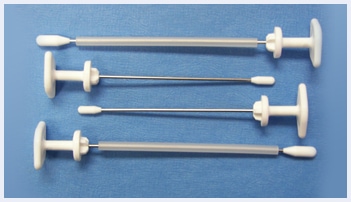

At AdvanTech Plastics, we provide plastic injection molding solutions to meet and exceed the needs of various applications. Customer satisfaction is our primary motivator, so we constantly improve our processes and develop lean manufacturing practices for excellent product quality and cost-effectiveness. Along with our general custom injection molding solutions, we also specialize in micro injection molding, a specialized field of manufacturing centered on creating small, extremely precise goods from thermoplastics and resins.

Micro Injection Molding Capabilities

Micro injection molding is a difficult manufacturing process capable of creating very small, very detailed parts in large quantities with next to no derivation from the original design. With a strong commitment to quality and accuracy, AdvanTech’s micro injection molding capabilities allow us to create optimal solutions for all of our clients’ micro part needs. Our dedication to quality is backed by the following:

- ISO 13485:2016 and ISO 9001:2015 certified as well as AIB approved

- ANSI, ASME, and ASTM compliant

We use specialized molding machines ranging from 55 to 400 tons and molding parts from 1.6 to 46 oz. shot sizes with tolerances up to +/-0.002 in. By focusing on precise shot control and the right techniques from start to finish, we guarantee ultra-fine resolution for every piece.

We work with the following thermoplastics and resins:

- ABS

- Acetal

- Acrylic

- Copolymer polypropylene

- HDPE/LDPE

- Nylon

- PEEK

- PET

- Polycarbonate

- Polypropylene

- Polystyrene,

- Polyvinyl chloride

- Thermoplastics