Because AdvanTech Plastics is involved in what’s known as “food-contact” packaging, our facility must regularly undergo inspections by officials at AIB International, the world’s leading organization advocating for food safety in manufacturing and packaging. Among its many contributions to the food industry, AIB International’s “Consolidated Standards for Food Contact Packaging Manufacturing Facilities” stand as the gold standard in this arena. In this article, we will delve into the significance of these standards, their impact on the packaging industry, and the critical role they play in ensuring the safety and quality of food contact materials.

The Essence of Food Contact Packaging Standards

Food contact packaging is a critical component of the food supply chain. It encompasses the materials and processes used to manufacture containers, wrappers, and other items that come into direct contact with food products. Ensuring the safety and quality of these materials is paramount to safeguarding public health and maintaining consumer confidence.

AIB International’s Consolidated Standards for Food Contact Packaging Manufacturing Facilities provide a comprehensive framework for achieving this goal. These standards are designed to assist manufacturers in developing and maintaining food-safe packaging materials and processes.

The Origins of AIB International

Before delving into the standards themselves, it’s worth noting the credibility and history behind AIB International. Founded in 1919 as the American Institute of Baking, the organization initially focused on improving the quality of bread and baked goods. Over the decades, AIB International expanded its scope to encompass food safety and quality in various sectors, including food contact packaging.

Key Components of the Standards

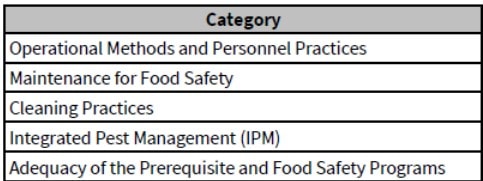

AIB International’s Consolidated Standards cover a wide array of aspects relevant to food contact packaging manufacturing facilities. Here are some of the key components:

- Facility Design and Construction: The standards provide guidelines for facility layout, construction materials, and sanitation practices to ensure that the manufacturing environment is suitable for food contact materials production.

- Personnel Practices: Proper training and hygiene protocols for employees are essential to prevent contamination. The standards detail the expectations for personnel handling food contact materials.

- Raw Material and Ingredient Handling: Stringent criteria are set for the reception, storage, and handling of raw materials and ingredients to prevent any potential hazards from entering the production process.

- Quality Assurance and Control: Comprehensive quality control measures are outlined, covering everything from material testing to production monitoring, to ensure consistent product quality.

- Cleaning and Sanitation: Thorough cleaning and sanitation practices are essential to eliminate any potential sources of contamination. The standards provide guidance on these critical processes.

- Documentation and Record Keeping: Adequate documentation and record-keeping practices are crucial for traceability and accountability. The standards specify the requirements for maintaining detailed records.

Global Recognition and Compliance

One of the most significant benefits of AIB International’s Consolidated Standards is their global recognition. In an increasingly interconnected world, where food packaging materials often cross borders, having a universally accepted set of standards is essential. Many packaging manufacturers worldwide choose to align with these standards to demonstrate their commitment to food safety and quality.

Moreover, compliance with AIB International’s standards can be a selling point for manufacturers. It provides a competitive advantage by assuring customers and consumers that products meet the highest food safety and quality standards.

Adapting to Evolving Needs

The food packaging industry is not static. It evolves in response to changing consumer preferences, regulatory requirements, and technological advancements. AIB International recognizes the need for ongoing improvement and regularly updates its standards to reflect the latest industry trends and best practices. This ensures that manufacturers can stay ahead of the curve and continue to provide safe and high-quality food contact materials.

Conclusion: A Pillar of Food Safety

AIB International’s Consolidated Standards for Food Contact Packaging Manufacturing Facilities play a vital role in upholding the integrity of the food supply chain. By providing a comprehensive framework for safety and quality, these standards empower manufacturers to meet and exceed the expectations of consumers and regulators alike. As the food industry continues to evolve, AIB International remains a trusted partner, guiding manufacturers toward the highest standards of excellence in food contact packaging.