Car manufacturers making ICU ventilators. E-commerce giants delivering testing kits. And plastic injection molding companies in Illinois and elsewhere making a variety of items to aid in the battle against COVID-19. Wherever you look, American industry is rolling up its sleeves to do its part in fighting this pandemic.

AdvanTech Plastics is part of that fight! As an “essential business,” AdvanTech Plastics has been running a portion of its molding equipment – five 300-ton molding machines – 24/7, churning out items such as:

- plastic caps for liquid nutritional supplements (mainly consumed by the elderly and those with underlying health issues — both high-risk groups)

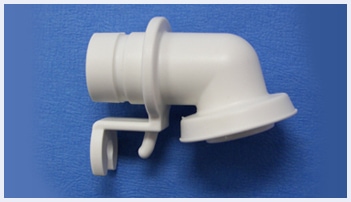

- plastic tracheotomy tubes (used in surgery and by patients at home)

In addition, AdvanTech distributes:

- plastic flip-tops and pumps for hand sanitizers

Just like other American manufacturers, AdvanTech has had to be flexible and creative, says Randy Kenyon, AdvanTech’s Director of Business Development. For example, the plastic flip-tops were originally manufactured for the food industry — destined to be used to dispense olive oil.

“The hand sanitizer customers told us they needed a million flip-top lids ASAP, and that they couldn’t wait 8-10 weeks for a shipment from China,” he says. “We told them we could help, but that the colors of the lids wouldn’t necessarily match the bottles. They said, ‘we don’t care!'”

When the U.S. automotive and dental manufacturing industries essentially shut down — both long-time customers of AdvanTech — the company suddenly found itself with a lot of unused manufacturing bandwidth. The pivot to hand-sanitizers and increased tracheotomy tube production for the healthcare industry was truly a shot-in-the-arm, Kenyon says.

“We’re very grateful for the extra work our plant personnel have put in,” he says. “With so many lay-offs around the country, we are truly blessed.”

Kenyon sees even more opportunity ahead, as more companies “re-shore” plastic molding production back to the U.S. from China. Rising labor costs and fears of more supply disruptions from China are driving those trends, he points out.

“We’re ready to take up the slack,” he says. “When this is all over, we’ll pivot again to meet the new demand.”