Quality Control in Plastic Injection Molding

Quality control in plastic injection molding encompasses a series of systematic measures and processes that monitor every stage of production. From material selection and preparation to mold design and tooling, all the way through the actual injection and cooling processes, and post-production inspections, quality control plays a vital role in maintaining high standards.

Ensuring Consistency

One of the primary reasons quality control is so critical in plastic injection molding is its ability to ensure consistency. Consistency in the manufacturing process directly translates into consistency in the final product. This means that each product coming out of the molding machine is virtually identical, with minimal variation in dimensions, appearance, and performance. This level of consistency is especially vital in industries like automotive, medical, and aerospace, where precise specifications are non-negotiable.

Minimizing Defects

Quality control measures are designed to detect and prevent defects. Defects in injection-molded parts can result in costly recalls, wasted materials, and, in some cases, safety hazards. By implementing rigorous quality control standards, manufacturers can identify and rectify defects before they reach the market, saving time, money, and reputation.

Meeting Industry Regulations and Standards

The plastic injection molding industry is subject to numerous regulations and standards, particularly in sectors like healthcare and automotive. Quality control is essential for ensuring that products meet these standards. Failure to comply with industry regulations can lead to legal issues, product recalls, and damage to a company’s reputation.

Customer Satisfaction

High-quality products lead to satisfied customers. Ensuring that your products consistently meet or exceed customer expectations can help build a loyal customer base and lead to repeat business. In an era of online reviews and social media, word-of-mouth recommendations and positive customer feedback can significantly impact a company’s success.

Cost Reduction

While implementing quality control measures may require an initial investment, it can lead to significant cost reductions in the long run. Detecting and rectifying defects early in the production process can prevent costly recalls and rework. Moreover, consistent quality can reduce scrap rates and the need for additional quality assurance measures, ultimately saving money.

Minimizing Waste and Environmental Impact

Quality control in plastic injection molding can also have a positive environmental impact. By minimizing defects, reducing waste, and optimizing the use of materials, manufacturers can contribute to a more sustainable and eco-friendly manufacturing process.

Strategies for Effective Quality Control

Quality control in plastic injection molding involves a combination of strategies and best practices. These include:

- Regular Inspections: Implement thorough inspections at various stages of the production process, from material selection to final product evaluation.

- Statistical Process Control (SPC): Use statistical methods to monitor and control the injection molding process, helping to detect variations and trends.

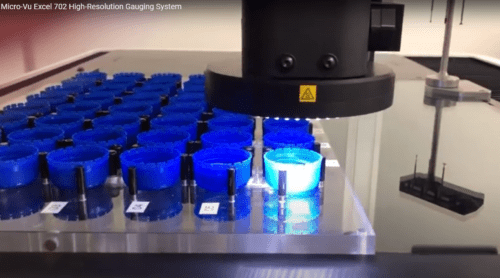

- Advanced Tools and Technology: Utilize advanced technology such as automated inspection systems and 3D scanning for precise measurements and defect detection.

- Employee Training: Ensure that your staff is well-trained in quality control procedures and understands the importance of their role in maintaining quality standards.

- Documentation: Keep detailed records of the quality control process to track trends, identify potential issues, and demonstrate compliance with industry standards.

- Continuous Improvement: Encourage a culture of continuous improvement, where feedback from quality control processes is used to refine and optimize the production process.

In conclusion, quality control is not just a requirement; it is the backbone of the plastic injection molding industry. It ensures that products meet specifications, adhere to industry standards, and exceed customer expectations. Quality control not only minimizes defects and reduces costs but also plays a significant role in building a company’s reputation and fostering customer trust. To thrive in the competitive plastic injection molding industry, manufacturers must prioritize and invest in quality control measures.