Plastics have literally broken the mold in the healthcare world, no pun intended.

In fact, plastic has easily kept up with the dizzying pace of medical science. With the advancements in the healthcare industry, plastic has proved to be one of the few materials that has been able to adapt along with the dynamic nature of the industry. Blood and fluid IV bags, disposable plastic syringes, new heart valves and other prosthetic devices, are just a few of the many ways plastics have come to be ubiquitous in healthcare.

1. One and Done: No Sterilization Needed

Plastics have been widely utilized to create disposable medical tools and devices such as:

- Surgical gloves

- Syringes

- Insulin pens

- IV tubes

- Catheters

- Inflatable splints

… and more. Such products are created for one-time use only and help prevent the spread of dangerous diseases by eliminating the need to sterilize and re-use a device. Plus, not having to sterilize these devices is a cost-saving.

But there’s more: specialty plastics are also being used to create antimicrobial surfaces that can repel and/or kill bacteria and other microbes, thus reducing disease spread.

2. Safety First, Last and Always

The durable nature of plastics makes it ideal for medical safety devices, such as:

- tamper-proof caps

- blister packs

- assorted medical waste disposal bags

Plastics are also shatter-proof and thus make for an optimal storage and transportation alternative. Moreover, plastics, by forming protective coatings, can be used to effectively preserve the integrity of other materials. For example, plastics are the material of choice for non-permeable biohazard bags which carry medical waste.

3. Plastic Has It All Over Metal

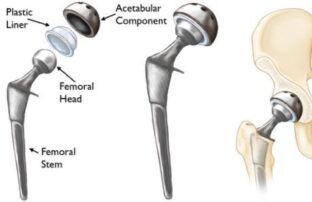

For decades, the healthcare industry used metal or metallic medical devices, especially for prosthetics. Today, because of its durability and versatility, plastic is used as a replacement for almost all metal prosthetic components. Plastics are not only much more comfortable, they are a safer, hypo-allergenic choice for patients who are allergic to certain metals,

4. Infinitely Malleable

Since plastic can be molded per the specifications of almost every specific medical application, it’s the material of choice for ground-breaking medical devices such as modern pacemakers, stents, or joint replacement prosthetics. In its molten state, plastics can fill the tiniest and most intricate molds.

5. Cheap, in a good way!

Bottom line: plastics can not only be cost-effectively mass-produced, they are ideal for the widest possible range of medical uses. You might say, plastics have proved their “mettle”!