Since it was invented in 1872, plastic injection molding has played an increasingly vital role in manufacturing various products that we encounter in our daily lives. From consumer goods to automotive components to medical devices, plastic injection molding enables the production of high-quality and cost-effective parts. In recent years, stack molds have emerged as a groundbreaking technology in our industry, revolutionizing the injection molding process. This blog post explores the concept of stack molds, their advantages, applications, and impact on every day life.

Understanding Stack Molds

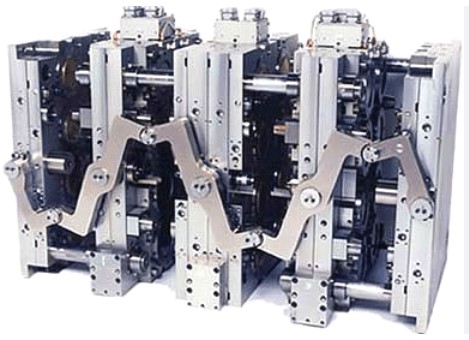

Stack molds, also known as multi-level or multi-tier molds, are specialized tools used in plastic injection molding to produce multiple plastic parts in a single molding cycle. Unlike conventional single-face molds, stack molds consist of multiple parting surfaces arranged in a vertical stack. This vertical configuration allows for the simultaneous injection of plastic material into multiple cavities, resulting in increased productivity and efficiency.

Advantages of Stack Molds:

- Enhanced Productivity: By integrating multiple parting surfaces into a single mold, stack molds facilitate the production of a larger number of parts per cycle. This leads to significant improvements in productivity and reduces overall manufacturing time. Increased productivity translates into cost savings, making stack molds an attractive option for manufacturers.

- Space and Cost Savings: Stack molds offer a space-efficient solution for manufacturing multiple components. By consolidating the production process, manufacturers can reduce the required factory floor space and lower the investment in machinery and equipment. This advantage is particularly beneficial for manufacturers with limited space or those looking to optimize their production lines.

- Design Flexibility: Stack molds enable the production of complex parts with varying features, such as undercuts, threads, and sliders, in a single molding cycle. This design flexibility eliminates the need for additional assembly or post-molding operations, saving time and resources. Moreover, stack molds allow for the molding of different parts with various materials, colors, or textures, expanding the possibilities for product customization.

- Improved Quality and Consistency: Stack molds ensure consistent part quality as all cavities are injected simultaneously under the same process conditions. This eliminates variations in part dimensions, appearance, and physical properties that may arise from different molding cycles. The enhanced control over the injection process results in higher quality parts and reduces the likelihood of defects.

Applications of Stack Molds:

Stack molds find applications in a wide range of industries, including automotive, consumer goods, electronics, and medical devices. Their ability to produce intricate components with high precision and consistency makes them invaluable for manufacturing products such as automotive interior panels, electronic connectors, medical device housings, and cosmetic packaging. The versatility and efficiency offered by stack molds make them a preferred choice in industries where cost-effectiveness, quality, and time-to-market are critical factors.

Here at AdavanTech Plastics, we are currently utilizing stack molds for two food manufacturers — a nationally-known spaghetti sauce manufacturer and a similarly well-known peanuts manufacturer.

Impact on the Plastic Injection Molding Industry:

Stack molds have emerged as a game-changing technology in the plastic injection molding industry. Their ability to increase productivity, reduce costs, and enhance design flexibility has transformed the way plastic parts are manufactured. As the demand for complex and customized plastic components continues to grow, stack molds will play a pivotal role in meeting these requirements efficiently and economically. With ongoing advancements in mold design and manufacturing processes, stack molds are set to drive further innovation and progress in the plastic injection molding industry, shaping the future of plastics manufacturing.