You see their ubiquitous “UL” label on products ranging from vacuum cleaners to laptops: Underwriters Solutions (formerly Underwriters Laboratories) is such a well-known logo, many people mistake it for a government seal-of-approval.

But Underwriters Solutions is a private company, albeit one that works closely with OSHA (Occupational Health & Safety Administration), a federal agency. And from its founding in 1894, UL has been involved in the testing and ratings of products for fire safety.

Today, their flammability ratings, bundled under the UL-94 banner, are THE standard in the plastic injection molding industry.

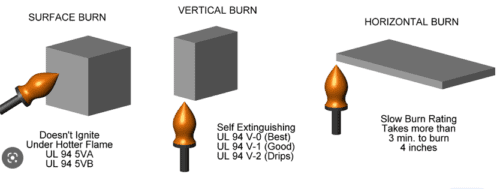

The UL 94 standard classifies materials based on their ability to extinguish flames, with the most stringent rating being UL 94 5VA. Widely used in industries such as electronics, automotive, and construction, products such as electronic housings, connectors, cables, and automotive components need to meet UL 94 ratings to ensure their safety and compliance with regulations.

Simply put, the standard evaluates materials based on two primary factors: burning rate and flame propagation. The burning rate measures how quickly a material burns, while the flame propagation measures how easily flames spread across the surface of the material. But these ratings are not intuitive; in fact, they can be downright confusing! So, herewith, a primer:

| UL 94 RATING | WHAT DOES THIS RATING MEAN? |

|---|---|

| HB | Horizontal plastic part will burn, but slowly |

| V-2 | Burning stops within 30 seconds on a vertical part but there will be dripping, flaming plastic |

| V-1 | Burning stops within 30 seconds on a vertical part with dripping non-flaming plastic |

| V-0 | Burning stops within 10 seconds on a vertical part but there are plastic drops that are not inflames. |

| 5VB | Burning stops within 60 seconds on a vertical part with no dripping plastic at all. However, test specimens may have a burn hole. |

| 5VA | Burning stops within 60 seconds on vertical part with no dripping plastic and no burn holes |

For AdvanTech Plastics, this means we need to know from our client which rating they require for their part. Recently we partnered with a sophisticated battery manufacturer who needed a plastic case that met a very stringent flammability rating of 5VA. After consulting with the client, we started with a base resin with no color additives because most of them don’t carry a UL rating. (It should be noted that additives such as slip agent, colorant, adhesives, etc. can alter the UL rating.) If a specific color was required, we could’ve worked with a resin compounder that could create a flame-retardant blend.

UL ratings are measured with a range of thicknesses that can drastically affect a parts UL rating. If you were looking to achieve a UL 94 5VA rating for a part with thin or thick walls, do your homework or your part could fail.

Bottom line: UL 94 flammability ratings are an essential factor in ensuring the safety and compliance of plastic materials used in various products. Manufacturers must choose materials with appropriate UL 94 ratings based on the products’ end-use and applicable regulations. Additionally, UL 94 ratings may vary depending on the testing laboratory, and it is crucial to consult with a certified testing facility to ensure accurate ratings.